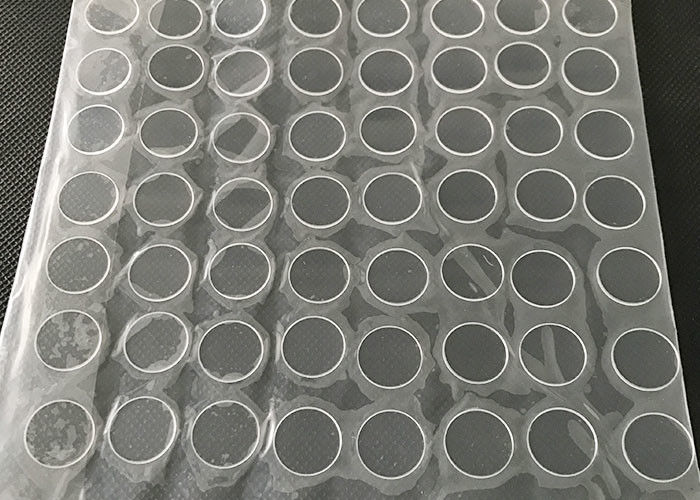

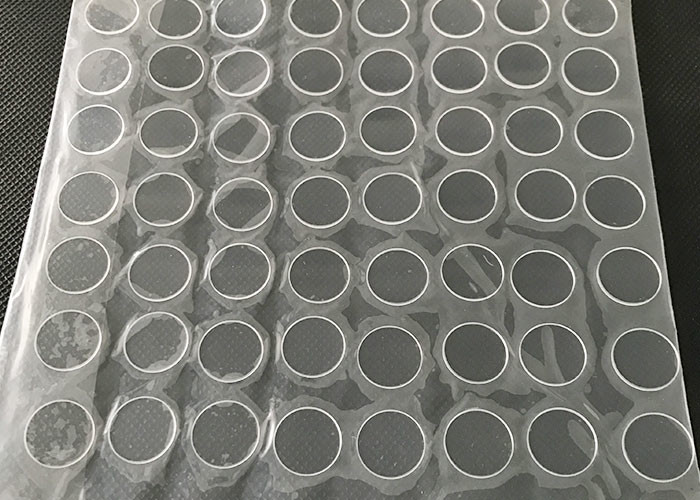

Infrared imaging system Sapphire protected windows

Features Extreme Surface Hardness Chemical Resistance

Transmits Wavelengths Ranging From UV to Mid-Infrared

Thinner and Stronger than Standard Glass Windows

Sapphire Windows are manufactured from single crystal sapphire, making them ideal for demanding applications because of their extreme surface hardness, high thermal conductivity, high dielectric constant and resistance to common chemical acids and alkalis. Sapphire is the second hardest crystal next to diamonds and, because of their structural strength, sapphire windows can be made much thinner than other common dielectric windows with improved transmittance. Chemically, sapphire is single crystal aluminum oxide (Al2O3) and is useful in a transmission range from 0.2 - 5.5μm.

Optical Properties of Sapphire Window

| Material |

Sapphire |

| Diameter Tolerance |

+0.0/-0.1 mm |

| Thickness Tolerance |

±0.1 mm |

| Parallelism |

1 arc min |

| Surface Quality |

60-40 Scratch-Dig |

Surface Flatness

(Plano Side) |

λ/2 at 633nm |

Surface Irregularity

(Peak to Valley) |

λ/2 at 633nm |

| Clear Aperture |

90% |

Transmittance

Sapphire properties

| Transmission Range |

0.17 to 5.5 μm |

| Refractive Index |

No 1.75449; Ne 1.74663 at 1.06 μm (1) |

| Reflection Loss |

14% at 1.06 μm |

| Absorption Coefficient |

0.3 x 10-3 cm-1 at 2.4 μm (2) |

| Reststrahlen Peak |

13.5 μm |

| dn/dT |

13.1 x 10-6 at 0.546 μm (3) |

| dn/dμ = 0 |

1.5 μm |

| Density |

3.97 g/cc |

| Melting Point |

2040°C |

| Thermal Conductivity |

27.21 W m-1 K-1 at 300K |

| Thermal Expansion |

5.6 (para) & 5.0 (perp) x 10-6/K * |

| Hardness |

Knoop 2000 with 2000g indenter |

| Specific Heat Capacity |

763 J Kg-1 K-1 at 293K (4) |

| Dielectric Constant |

11.5 (para) 9.4 (perp) at 1MHz |

| Youngs Modulus (E) |

335 GPa |

| Shear Modulus (G) |

148.1 GPa |

| Bulk Modulus (K) |

240 GPa |

| Elastic Coefficients |

C11=496 C12=164 C13=115 C33=498 C44=148 |

| Apparent Elastic Limit |

300 MPa (45,000 psi) |

| Poisson Ratio |

0.25 |

| Solubility |

98 x 10-6 g/100g water |

| Molecular Weight |

101.96 |

| Class/Structure |

Trigonal (hex), R3c |

Sapphire (Al2O3) is one of the hardest minerals and optical materials available for use in the range from UV up to about 5µm. Sapphire is birefringent and if its use is for critical optical application, for example, windows, then the crystal might have to be cut along the zero degree plane, or c-cut. Random cut is usually cut along a plane that is 60° off-axis as the growth in this direction is the easiest to grow. Random cut is anyone that is not the C-Cut angle. Sapphire can fluoresce and that depends upon the concentration of other minerals within the lattice, for example Iron (Fe) or Chromium (Cr). Clear Sapphire might fluoresce orange when illuminated by UV light if impurities are in the crystal. Fluorescent free Sapphire has to be grown from 'pure' feedstock and seed and in an environment that cannot place impurities into the lattice.

Sapphire is grown by various methods from seed samples. Sapphire can be polished to a high standard, but as it is the second hardest mineral on Earth it must be subject to high forces to get the polish. Therefore, windows made from Sapphire must have a thickness to diameter ratio of at least 10:1, that is, greater than 10mm thick for a 100mm diameter disk. Sapphire is inert and resistant to attack from most processing environments, such as hydrofluoric acid. Sapphire has a melting point over 2000°C with a high thermal conductivity makes it suitable for use in harsh environments.

Sapphire is ideal for use as a window where high radiation resistance is required from the UV to about 5µm. It can be used to form doublet lenses with Silicon and Zinc Selenide for the MWIR (3 to 5µm). These optics can be used to, for example, detect missile plumes that emit the 3-5 µm range and shorter, wavelengths. The detection of muzzle flash from a sniper can be 'seen' by use of optics in this MWIR waveband. The detection of snipers is of great importance in, for example, Afghanistan, as many military lives are being lost to snipers. The gun flash from a rifle has a distinct spectral distribution from the hot gases that are emitted. These gasses are, for example, CO and H2 together with CO2, N2 and H2 O that produce distinct emissions in the 3 to 5µm band.

Sapphire is used as a host for various elements, for example titanium (Ti), to produce laser rods for efficient laser systems for R&D laboratories and military uses. This use could be for defensive systems to, for example, dazzle enemy pilots or incoming optically guided weapons.

Knight Optical supply a large range of stock Sapphire Window in both Random and C-Cut options to meet most applications. We offer stock Sapphire Windows in both large and small aperture sizes. Please click the links below. Stock windows can be edged to small diameters or machined to square and rectangular shapes at short notice. Please enquire.

Infrared Elements Selection Guide

Procedure

What's the way of shipping?

We accept DHL, Fedex, TNT, UPS, SF, EMS etc. If you have your own express account, it's great.

How to pay?

(1) T/T, PayPal, West Union,etc

(2) Bank Fee: West Union-USD30.00(≤USD3000.00),

T/T-USD20.00+, PayPal-5%. Please consult the local bank.

What's the deliver time?

For inventory: the delivery time is around 5 workdays.

Customized products: the delivery time is 10 to 30 workdays. According to the quantity and precision.

Can I customize the products based on my need?

Yes, we can customize the material, specifications and optical coating for your optical components based on your needs. OEM is available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!